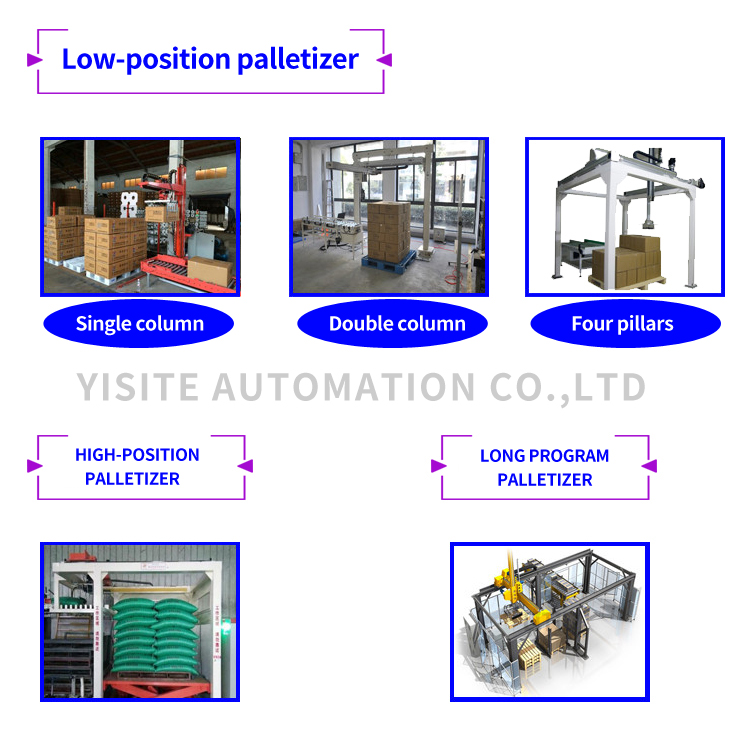

Ibicuruzwa

imifuka yikora gantry palletizer

Gupakira igikapu cyuzuye cyikora truss ikora palletizing manipulator

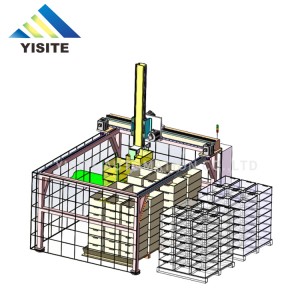

Imikorere ya palletizing yikora izahita itondekanya neza (cyangwa gusenya) kumurongo (cyangwa umurongo utanga umusaruro, nibindi) byuburyo butandukanye nubunini bwapakiye.Kugirango ukoreshe byuzuye agace ka tray hamwe nuburinganire bwibintu bifatika . ikoreshwa mu nganda zikora imiti, plastike, ibikoresho byubaka, imiti, ibiryo, ibikoresho bya batiri nizindi nzego zitandukanye.

ents, imikorere ihamye, imikorere yizewe kandi iramba.

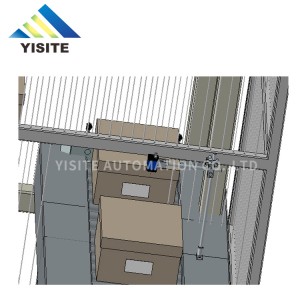

3. Ibikoresho byo gukingira biratangwa.Iyo urugi rutwikiriye rufunguye, imikorere yimashini irahagarara.

4. Guhindura uburyo bwo gutondeka biroroshye kandi byoroshye, kandi birashobora gukorwa kuri ecran ya ecran.

5. Inzira nyinshi zo gutondeka zirashobora kurangizwa udasimbuye ibice.

6. Bihujwe na tray 2, gukora neza kandi byihuse

Ibyiza bya automatic palletizing manipulator

1. Byoroshye kandi byoroshye: gupakira imifuka no gukoresha robot palletizing igizwe nubwikorezi bugendanwa hamwe nudupaki twa palletizing manipulator, robot palletizing ifite ibyiza byoroheje, byoroshye, imbaraga nto, kuzigama ingufu, igiciro gito nibindi byiza;

2.Kuzigama kubakozi no kunoza imikorere: robot ikora palletizing irashobora kurangiza gufata, gufata, gutekera imifuka nibicuruzwa bipfunyika, bishobora kuzigama cyane amafaranga yumurimo no kuzamura imikorere yimishinga;

3. Umuvuduko wihuse hamwe no gutondekanya neza: ibikoresho byo gutekera mu mufuka byikora birashobora gukora igikorwa cyo gutondekanya mu buryo bwikora bwimifuka itandukanye, hamwe nibiranga umuvuduko wihuse, gutondeka neza no kurwego rwo hejuru rwihuta;

4

5. Igikorwa cyoroshye kandi cyoroshye: igikapu cyo gupakira gikapu cyikora gishobora gushyirwaho mumwanya muto, kandi cyimuwe neza kumwanya wagenwe ukurikije inzira yashyizweho numukoresha.Igenzura ryose rishobora gukorerwa kuri ecran ya kabine, kandi imikorere iroroshye;

6. Imikorere ihindagurika: guhagarika no gutondekanya ibicuruzwa bitandukanye birashobora kurangizwa no gusimbuza clam gufata ya manipulator, bityo bikagabanya ikiguzi;

7